PRODUCTS

Frying

Foodco is offering high-technology equipment for different air and oil frying systems, always with a minimum of product waste.

The frying plant E 400 is a batch unit built for frying meat, poultry and pasties. The frying plant model CCR transfers products through the cook/flash roasting unit with a cook/roasting temperature range between 100 to 290oC. The cook/roasting time is approx 5 to 60 minutes, or other depending on product and belt speed. Last but not least, Foodco’s B4 series of oil frying system has a frying zone of different sizes depending on product and capacity.

PRODUCTS

Frying

Foodco is offering high-technology equipment for different air and oil frying systems, always with a minimum of product waste.

The frying plant E 400 is a batch unit built for frying meat, poultry and pasties. The frying plant model CCR transfers products through the cook/flash roasting unit with a cook/roasting temperature range between 100 to 290oC. The cook/roasting time is approx 5 to 60 minutes, or other depending on product and belt speed. Last but not least, Foodco’s B4 series of oil frying system has a frying zone of different sizes depending on product and capacity.

FRYING SYSTEMS

Foodco Fryers

Foodco’s E400 and E800 Fryer >>

Foodco’s Oil Fryer B42 – B86 >>

Foodco’s Continuous Cook – Flash Roasting Tunnel >>

FRYING SYSTEMS

Foodco’s E400 and E800 Fryer

The frying plant E400 or E800 is a batch unit programmed for frying meat, poultry, and pasties with a minimum product waste where the quality of the product will not deteriorate.

These frying plants have heat produced by steam or electricity. The heating coils make a direct transmission of the heat to all sides of the product, while the heat control is programmed to the best outcome for you.

Advantages

By adding steam via a program makes it possible to reduce the waste without changing the quality of the product. The direct infrared radiation from the heating coils ensures the wanted degree of the burning of the product.

Production capacity (standard building) :

- Capacity per net: 4000 cm2

- No of nets: 16 pcs per stand

- Max production height: 85 mm

FRYING SYSTEMS

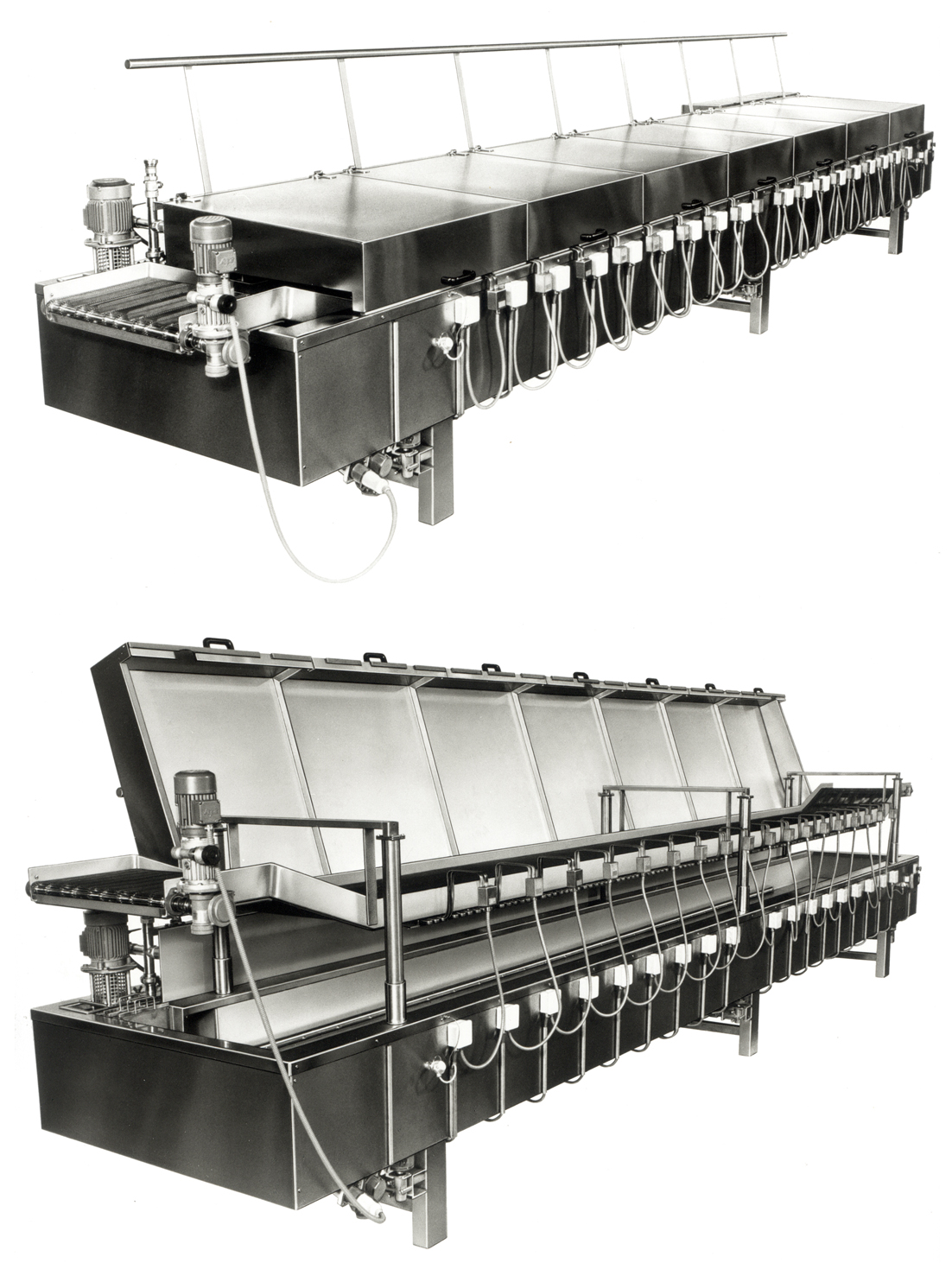

Foodco’s Oil Frying Machine type B42 – B86

The Foodco oil fryer is suitable for continuous frying of products like poultry, meat, vegetables, and fish in any form or shape. Depending on the fryer’s design, coated as well as non-coated products can be handled and be flash or fully fried. The frying machine has a frying zone of different sizes depending on the product, capacity, and consists of a conveyor leading the products into a heated oil vessel. The B42 and B86 are electrically heated or with other media. The heating elements are made of stainless steel and have a big surface considering their effect. In this way, the frying oil is not decomposed due to overheating.

Advantages

- The frying belt can be removed from the machine with the built-in lifting equipment for cleaning.

- The pump circulates oil and can be used to empty the machine of frying oil too. Effortlessly, the whole pump system can be removed and separated for cleaning.

- The PLC control system is built into a stainless steel panel placed on one side of the machine.

FRYING SYSTEMS

Foodco’s Oil Frying Machine type B42 – B86

The Foodco oil fryer is suitable for continuous frying of products like poultry, meat, vegetables, and fish in any form or shape. Depending on the fryer’s design, coated as well as non-coated products can be handled and be flash or fully fried. The frying machine has a frying zone of different sizes depending on the product, capacity, and consists of a conveyor leading the products into a heated oil vessel. The B42 and B86 are electrically heated or with other media. The heating elements are made of stainless steel and have a big surface considering their effect. In this way, the frying oil is not decomposed due to overheating.

Advantages

- The frying belt can be removed from the machine with the built-in lifting equipment for cleaning.

- The pump circulates oil and can be used to empty the machine of frying oil too. Effortlessly, the whole pump system can be removed and separated for cleaning.

- The PLC control system is built into a stainless steel panel placed on one side of the machine.

FRYING SYSTEMS

Continuous Cook – Flash Roasting Tunnel

Foodco’s Continuous Cook – Flash Roasting tunnel is automatically measuring the processing time depending on the time of transferring the products through the cook – flash roasting unit and the cook – roasting. The cook – roasting time is approx 5 to 60 minutes, depending on load and belt speed. Electrically heated elements and individual fans along the centre line of the tunnel will distribute the energy evenly to give a perfect roasted product.

Function

The transport belt is manufactured with stainless steel mesh belt with a width from 400 to 1000 mm, and shafts for support to achieve the correct and proper drive. The transport belt is held up, inside the roasting tunnel, with a stainless steel framework, built for safe and correct transportation of the products loaded onto the mesh belt.

The belt is operated by a frequency-controlled and adjustable motor that is easily controlled from main switchboard.

REFERENCE LIST

Mills, Norway | Öresundschark, Sweden | Orkla ,Sweden | Miratorg, Russia | X5, Russia | Celestino, Spain | Lero, Russia | Slatur Felag, Iceland | Roach Foods, UK | Abdallah Al, Saudi | Karjaportti, Finland | Swedish Meats, Sweden | Nortura, Norway | Purovsk, Russia | Atria, Finland | Marlow Foods, UK | Eldrob, Polen | Tulip, Denmark | Atyraubalyk, Khazakstan | Olsztynskie, Zaklady Polen | Stabburet, Norway |

PROJECTS

Want to learn more about our finished projects?

Have a look at our already completed projects, or if you know what you are looking for, feel free to reach out and we’ll schedule a call.

OTHER PRODUCTS

Control Systems

Continuous lines

Smoking plants

Defrosting

Loader & Unloader

Fryer

Cooking

Hot Air Fryer

GET IN CONTACT

Looking to start a project?

WE’RE HERE TO ANSWER THE QUESTIONS YOU MIGHT HAVE